Energy Efficient

Continuous Steamer

Steam Sterilization & Cooling System

SUNPLUS energy-efficient continuous steamer automates the entire process from product input to extraction, ensuring uniform work quality. Special piping technology minimizes steam leakage, maximizes steam utilization efficiency, improving product quality and achieving energy savings.

Use For

Low Temperature Pasteurization (45°C–98°C)

Cup containers, bottle containers, pouches, stand pouches, spout pouches, deep drawing, pillow packaging, portion cups, and others.

Features

-

Considerable Cost Reduction and Energy Savings

Considerable energy savings (30%–80%) and cost reduction is possible with maximum efficient use of steam and minimum radiation of heat. Steam leakage is also extremely small.

-

Balanced High Quality Control

Automatic temperature control maintains temperature within 45°C–98°C, ensuring uniform high-quality production without damaging food flavor, fragrance, or color.

-

Reduction of Work Time and High Productivity

No warm water is required, heating time is short, no wastewater disposal needed, reducing work time and expenses.

-

Extremely Hygienic and Safe

No mold from steam leakage or warm water contamination. No warm water heating process greatly reduces risks.

-

Reduction in Equipment Investment

No need for pumps, hoods, or ducts as warm water heating is unnecessary and steam leakage is minimal.

-

Auto Tension System

Equipped with auto tension system to minimize chain trouble, ensuring stable steamer operation. Cooling by water shower method or air cooling method available.

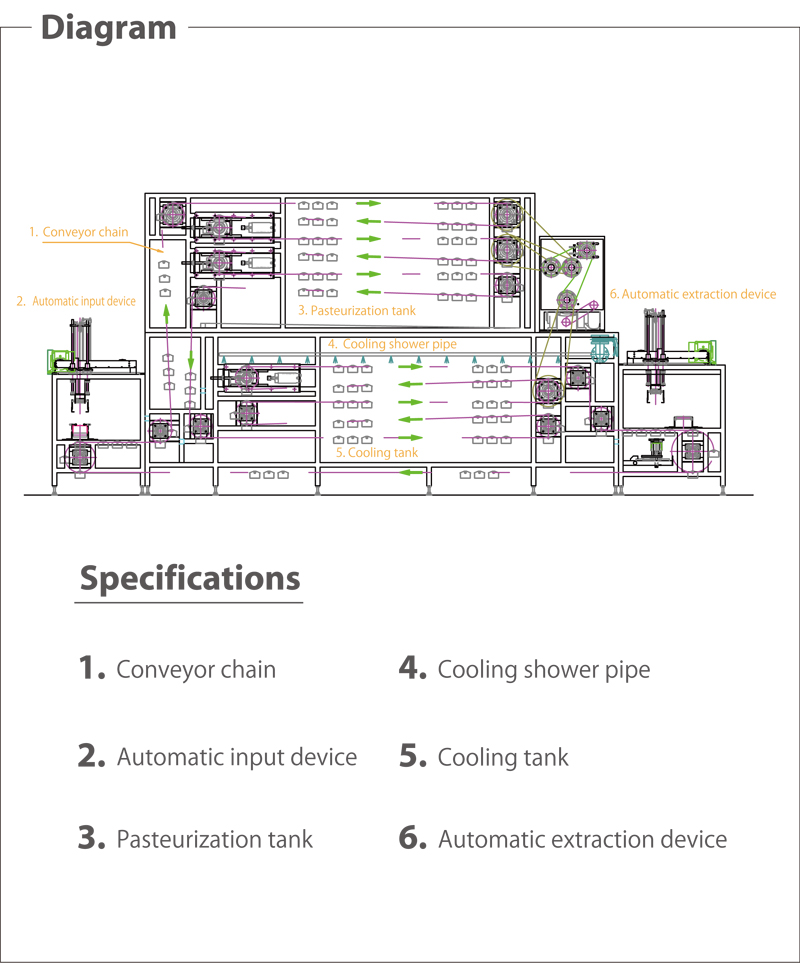

Diagram

Technical Specifications

Usable Temperature Range: 45°C–98°C

Steam Pressure: Low to medium pressure compatible